Acoustic insulation

Limiting the noises heard from inside the vehicle, particularly in the passenger compartment, is a major challenge for car manufacturers. Adhex offers high quality acoustic insulation solutions based on perfectly mastered technologies.

During its use, a vehicle produces all kinds of noise: in addition to the noise from driving and traffic, there are noises such as slamming, vibrations, crackling, friction… the acoustic insulation systems designed by Adhex make it possible to strongly reduce this noise volume, for the greatest comfort of the passengers. The challenge is to create an acoustic barrier against contact noise, sound rising through hollow bodies but also abnormal carbody noises, and this regardless of the outside temperature (from -20 to +85 degrees). Our parts are thus nested in the belt housings, the custodes or the car fenders. To achieve the acoustic performance desired by car manufacturers, Adhex has developed a range of insulators using materials compatible with the parts in contact. The parts are mainly made of flat or thermoformed foam capable of accommodating products that absorb noise as well as possible. Ensuring the design of the parts (their shape, thanks to Catia, and their composition) as well as their manufacture, we work in close collaboration with the technical departments of the brands, in order to respond quickly to their requirements, with an impeccable level of performance and quality.

Our range of acoustic insulation

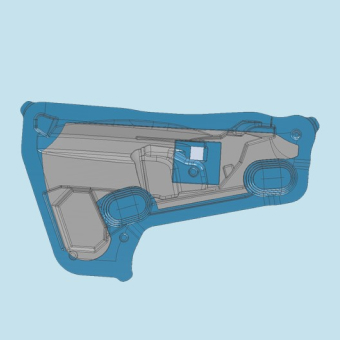

TA3_FOP100-2.2_HBPP_AP400

Acoustic adhesive foam 100 door water shield

- Acoustic patch: Adhesive acoustic fiber of 400g/sqm (Adhex XL Pad 400)

- Carrier: White polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

- Integration of sound absorption patch (400g/sqm)

- Ideal lightweight solution for perfect water, air and dust tightness

- Bonding on painted sheet metal, plastic smooth or grained PP parts

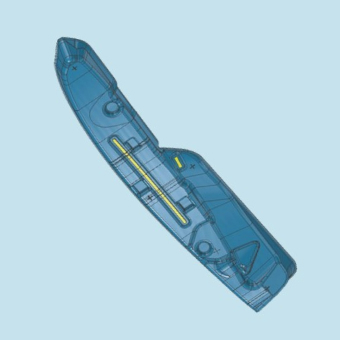

FA3_FOP270-3_HBPP_AF

Adhesive foam 270 for sound insulation

- Carrier: Black polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

- Lightweight solution ideal for fender acoustic insulation

- Bonding on painted sheet metal, plastic smooth or grained PP parts (fixation)

TA3_FOE900-3_HBPP_AC900

Acoustic adhesive foam 900 door water shield

- Acoustic patch: Adhesive acoustic cotton felt of 900g/sqm (Adhex XL Drypad 900)

- Carrier: Grey polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

- Excellent acoustic level (hifi version)

- Integration of sound absorption patch in dry area

- Excellent acoustic performance (insulating solution 900g/sqm)

- Bonding on painted sheet metal, plastic smooth or grained PP parts

FA3_FOE900-3_HBPP_AP530VI

Acoustic adhesive foam 900 door water shield

- Acoustic patch: Adhesive acoustic fiber of 530g/sqm (Adhex XL Pad 600)

- Damping patch (anti-vibration): Heavy adhesive mass of 7,5kg/sqm (IFF)

- Carrier: Grey polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

- Excellent acoustic level (hifi version)

- Integration of sound absorbing and anti-vibration patch

- Excellent acoustic performance (insulating solution 900g/sqm)

- Bonding on painted sheet metal, plastic smooth or grained PP parts

Discover other applications in the thermoformed plastic foams and films segment

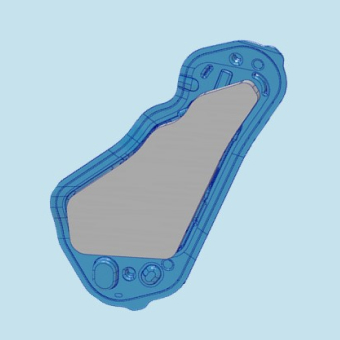

Screen sealer / Door water shield

The panels installed in the doors ensure that the vehicle is sealed against water, air, noise and dust. Reliable, lightweight and made to last, they meet the highest quality requirements.

Thermal protection

In order to create an efficient thermal barrier between the engine compartment or the outside air on the one hand, and the passenger compartment on the other hand, Adhex has developed a wide range of thermoformed polyolefin foam parts contributing to the comfort of use of the vehicle.