Backings for Conventional Wound Care

Optimal protection, backings with high mechanical resistance and comfort on the skin, the conventional wound care range developed by Adhex offers high performance and complies with biocompatibility standards.

Innovations recently performed by Adhex allowed the development of a wide variety of high-performance dressings. A real second skin, the adhesive materials are completely forgotten by the end user and adapt to the requirements of their daily life: comfort, breathability, painless removal, high resistance, impermeability, aesthetics (invisibility), elasticity…

This comfort combined with the performance of the dressing is gained by selecting appropriate materials as carriers and adhesives. Indeed, our wide range of backings available allows to obtain heterogeneous performances according to the desired needs: high breathability, elasticity, second skin feeling and visual invisibility while preserving its primary function of wound protection.

Polyurethane films with thin thicknesses (from 20 to 50µm) and complexes (laminates based on TPU Meltblown) is a unique process that makes it possible to obtain a high-performance dressing with improved breathability and elasticity. Then, working on different chemistries (solvent, cross-linked hot-melt, water based) which guarantee less traumatic removal, Adhex has also taken into account the physical and mechanical parameters of the adhesive materials: thickness, respect of the width for dressing converting; quality of the films between the adhesive and the release liner…. Chemistries coating, backing microperforation or embossing, lamination of different materials, so many technical processes which enables Adhex to get a unique and adapted bandage. Our materials have undergone numerous biotoxicity tests. Developments are carried out in compliance with the MDR (Medical Device Regulation) and respect the ISO 10-993 standard.

Our range of backings especially designed for your bandages

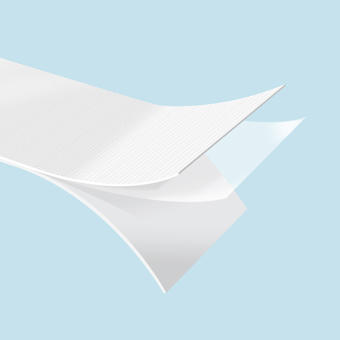

P570LL

Single coated white PET non-woven

- Carrier: White PET non-woven 45 g/sqm

- Adhesive: Solvent acrylic 35 g/sqm

- Liner: White paper one side siliconized 81 g/sqm

- Higher skin adhesion

- Breathable

- Soft touch and conformable backing

P1287

(Temporary) Single coated transparent PU film

- Applicator: Transparent PE film 50 g/sqm

- Carrier: Transparent PU film 25 g/sqm

- Adhesive: Water-based acrylic adhesive 25 g/sqm

- Liner: White paper one side siliconized 80 g/sqm

- Good skin adhesion

- Eco-friendly adhesive

- Highly breathable thanks to optimum carrier / adhesive combination

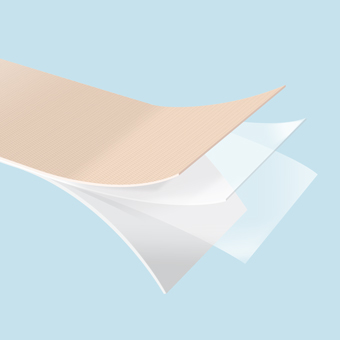

P1125

Single coated beige color PE film

- Carrier: Beige color PE film 55 g/sqm

- Adhesive: Solvent free acrylic 30 g/sqm

- Liner: White paper one side siliconized 62 g/sqm

- Beige color PE film backing

- Resistant

- Eco-friendly adhesive

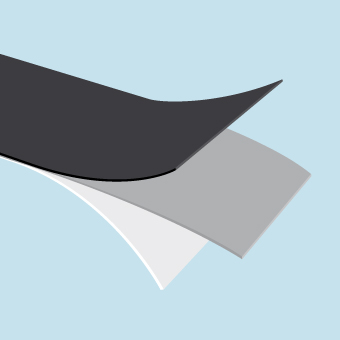

P1159-1

Single coated DMF-free transparent PU film

- Applicator: White paper one side siliconized 121g/sqm

- Carrier: Transparent PU film 25 g/sqm

- Adhesive: Solvent acrylic 25 g/sqm

- Liner: White paper one side siliconized 63 g/sqm

- Highly conformable and breathable

- Easy to convert or die-cut due to applicator thickness

- DMF-free adhesive PU film

P1502

Single coated beige TPU non-woven with laminated PU film

- Carrier: Beige TPU non woven 45g/sqm laminated with PU film 30g/sqm

- Adhesive: solvant acrylic adhesive 25g/sqm

- Liner: white paper one side siliconized 100g/sqm

- High cutaneous tolerance

- Conformable and elastic

- PU layer guarantees product waterproofness

- Breathable

Find out our other applications involving skin adhesion

Advanced Wound Care

Professional Woundcare: low trauma adhesion, higher MVTR materials including technical product laminations, and tapes for NPWT systems.

Adhesive tapes for topical reservoir patches

Wide range of adhesive layers and solutions for transdermal and topical patches manufacturers.