Adhesive tapes for topical reservoir patches

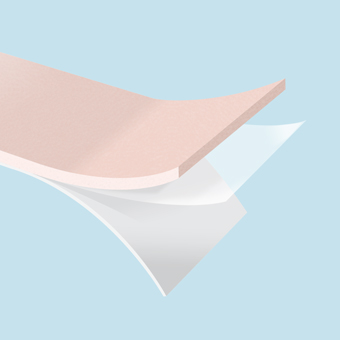

Patch securement on the skin allowing precise and controlled release of the active ingredient, occlusive foam preserving the drug from any contamination with the adhesive surface… Resevoir patch backings’ performances designed by Adhex ensure optimal skin adhesion and easy removal of the protective film while respecting biocompatibility constraints.

Adhex has strengthened its quality teams in recent years to comply with the pharmaceutical industry important regulatory constraints. The adhesive formulations and carriers developed for topical patches offer optimal skin performances and comply with all the major standards (ISO 10993, Drug Master File EU/US). The reservoir patch adhesive technologies got an excellent skin tolerance while preserving the API. They avoid any interaction with the molecule to ensure its effectiveness during the transdermal process. Our adhesive solutions are then positioned as a packaging for topical patches. Our custom made adhesive tape for pharmaceutical use has been designed to be associated with different types of materials (foams and adhesive films) and different colors (white, beige…). These carriers are printable with inkjet technology allowing to specify the patch component molecule. Finally, various release liners are available and can be reused during the patch manufacturing step (with silicones treatment, PE coating…).

Our adhesive facestocks validated for Pharma / reservoir patches usages

P917

Single coated beige PE foam

- Carrier: Beige PE foam 0.8mm (95 kg/m3)

- Adhesive: Solvant acrylic 42 g/sqm

- Liner: White paper one side siliconized 140 g/sqm

- Occlusive beige PE foam

- Good skin adhesion

- Suitable for reservoir patches manufacturing

P1159

Single coated transparent PU film

- Applicator: White paper one side siliconized 121 g/sqm

- Carrier: Transparent PU film 25 g/sqm

- Adhesive: Solvent acrylic 25 g/sqm

- Liner: White paper one side siliconized 63 g/sqm

- Good skin adhesion

- Breathable and conformable carrier

- Easy to die-cut / convert thanks to liner thickness

Find out our other Pharmaceutical applications

Consumer Wound Care

Optimal protection, backings with high mechanical resistance and comfort on the skin, the conventional wound care range developed by Adhex offers high performance and complies with biocompatibility standards.