Patch: adhesive securement and covering

Optimized adhesion and patch recovering, breathability… the transdermal patch covering dressings designed by Adhex increase the adhesive area with no maceration for several days. They also do preserve the active ingredient while taking into account the importance of the regulatory aspect (DMF).

Securement and fixation of opioid, nitroglycerine, smoking cessation patches… Adhex matrix patch covering range has been developed by its R&D teams to improve adhesion performances by relying on the regulatory constraints and market standards (Drug Master File EU and US, ISO 10993). The adhesive portfolio proposed by Adhex is thus approved for skin contact and validated for pharmaceutical use. Transdermal matrix patches covering (systemic activity in relation to the blood system) or reservoirs offer an impressive number of additional skin contact points and adhesive surface improvements allowing the patch to last for one to several days as required (24 to 72 hours). These devices also meet breathability requirements to avoid the risk of maceration (> 800g/m²/24h). Thanks to a vertical integration, Adhex controls all the manufacturing steps, from coating to converting. Choice of adhesive materials: non-woven, TPU Meltblown, polyurethane films, printing of logos with inkjet technology allowing to specify the components of the patch, choice of release liners to facilitate die-cutting into patch, security films : siliconing, PE coating, choice of designs to simplify handling of the device: cuts, backsplits, IFU printing… Adhex offers fully customizable solutions.

Our adhesive technologies for Patch covering

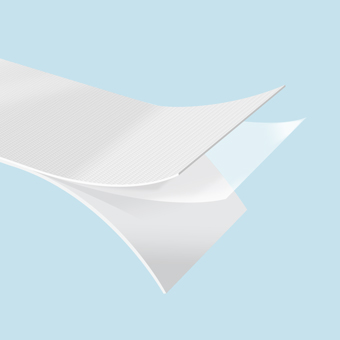

P1159

Single coated transparent PU film

- Applicator: White paper one side siliconized 121 g/sqm

- Carrier: Transparent PU film 25 g/sqm

- Adhesive: Solvent acrylic 25 g/sqm

- Liner: White paper one side siliconized 63 g/sqm

- Good skin adhesion

- Breathable and conformable carrier

- Easy to die-cut / convert thanks to liner thickness

P1501

Single coated white TPU Meltblown

- Carrier: white Meltblown thermoplastic polyurethane 60g/sqm

- Adhesive: solvant acrylic adhesive 50g/sqm

- Liner: white paper one side siliconized 62g/sqm

- High cutaneous tolerance

- Conformable and elastic TPU material

- Highly breathable

- Easy to die-cut

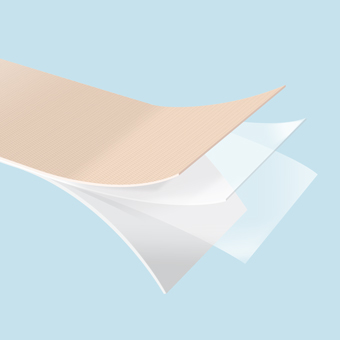

P1502

Single coated beige TPU non-woven with laminated PU film

- Carrier: Beige TPU non woven 45g/sqm laminated with PU film 30g/sqm

- Adhesive: solvant acrylic adhesive 25g/sqm

- Liner: white paper one side siliconized 100g/sqm

- High cutaneous tolerance

- Conformable and elastic

- PU layer guarantees product waterproofness

- Breathable

Learn more about our other skin contact applications

Adhesive tapes for topical reservoir patches

Wide range of adhesive layers and solutions for transdermal and topical patches manufacturers.

Consumer Wound Care

Optimal protection, backings with high mechanical resistance and comfort on the skin, the conventional wound care range developed by Adhex offers high performance and complies with biocompatibility standards.