Our unique know-how for the design of your medical device

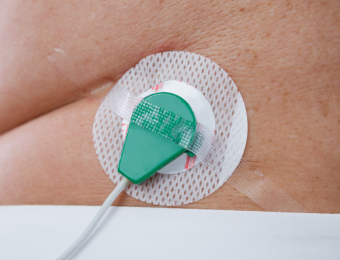

Spacer tape or sensor securement, Adhex medical device assembly range provides all the guarantees to optimize adhesion and hold any device.

Adhex’s expertise in adhesive chemistry and bonding techniques offers many benefits for werable devices (conformability, robustness and resistance or breathability). Thus these sensors make the measurements and body parameters to be taken into account more reliable (glucose, blood sugar, elderly monitoring, sports performance calculation…).

The industrial know-how also enables Adhex to provide answers to all your medical device development issues given the substrate type and nature (skin bonding or not), while facilitating cutting in strict compliance with your process tolerances. Single-sided, double-sided or transfer adhesive, Adhex selects the most suitable materials to provide the essential component of your medical device.

For more than thirty years, Adhex has been established as a major partner of the medical community by answering all medical devices production constraints. Vertical integration allows Adhex to control the entire chain, from coating to converting, guaranteeing that your adhesive element or component will be manufactured in a fully controlled atmosphere.

Find out required adhesive components for your medical device

Wearable devices securement and fixation

Fixation and securement adhesive tapes for your wearable medical device: from a few minutes to several days.

Adhesive Tapes For Medical Devices Assembly

Wide range of adhesive tapes for Medical device components lamination and assembly

Discover supplementary medical applications

Electromedical

Wide range of adhesive backings and hydrogel for Electrodes and ESU plates manufacturing

Medical device identification and traceability

Labelling solutions for medical industry's challenges: Medical Devices identification, safety and traceability