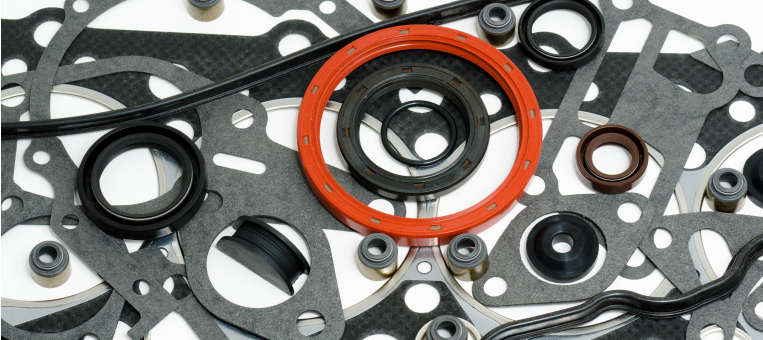

Protective die-cut adhesive parts

Air, water, dust, bad weather and thermal variations, vibrations and shocks: Adhex protects every vehicle thanks to its wide range of die-cut adhesive parts.

On the production line, then during transport and of course throughout its life, each vehicle is subject to aggressions that require protecting its most sensitive elements. Adhex has developed technical parts adapted to the specific needs of each vehicle manufacturer and each model, highlighting its perfect mastery of adhesive technologies. Protective die-cut adhesive parts can be produced by using various manufacturing techniques, depending on the needs: laminage, lamination, cold cutting, rotary… They are made of various materials: thin or thick foams (PVC, polyurethane, polyethylene…) and metallic films (zinc, aluminium…) in particular. They can be fixed on all substrates (plastic, sheet metal…), and if necessary, they are combined with technical fastening adhesives, which enable a sealing gasket, a door sill or an emblem to be fixed reliably. Adhex protective parts help to prevent corrosion, water, air, dust, stone chips, noise from vibration, bumping or slamming of doors and boot – and thus contribute to better sound insulation. They protect the various sensitive parts of the vehicle both permanently and temporarily – such as, for example, protections put in place around the vehicle during transport.

Our range of protective die-cut adhesive parts

P228

Black adhesive felt

- Carrier: Black Polyester felt

- Adhesive: Acrylic hot melt

- Liner: Brown kraft paper

- Compatible with low energy surfaces or greasy surfaces

- Reducing noises such as friction, vibrations or shocks between components inside the vehicle

P402

Transparent glossy adhesive PVC film

- Carrier: Transparent glossy calendered PVC film

- Adhesive: Solvent based acrylic

- Liner: Anti-adherent 2 sided polyethylene coated paper

- Product conformability, printability and excellent UV-resistance ensure a sustainable utilization outside the vehicle.

- Excellent protection of friction, abrasion and scratch sensitive areas.

P630

Zinc adhesive special grease surface

- Carrier: Zinc sheet Z1 purity 99,995%

- Adhesive: Water based acrylic double-sided on non-woven backing

- Liner: Brown two sided non-stick paper

- Special to bonding on grease surface

- Sacrificial anode (consumable anode) in the case of cathodic protection of metals

P631

Zinc adhesive

- Carrier: Zinc sheet Z1 purity 99,995%

- Adhesive: Solvent based acrylic

- Liner: White non-stick paper

- Special to bonding on clean surface

- Sacrificial anode (consumable anode) in the case of cathodic protection of metals

P1009

Grey adhesive PP Non-woven

- Carrier: Grey PP non-woven

- Adhesive: Water based acrylic

- Liner: Brown non-adherent polyethylene coated paper

- Excellent adhesion on low surface energy

- Very good resistant against friction and scratch

- Limits a friction noise

- Printable

P1019

Black adhesive PP Non-woven

- Carrier: Black PP Non-woven

- Adhesive: Solvent based acrylic

- Liner: Brown non-adherent polyethylene coated paper

- Applicable on low surface energy and painted steel plate

- Very good resistant against friction and scratch

- Limits a friction noise

Discover other applications in the automotive die-cut adhesive parts segment

Hole covering & adhesive sealing elements of car body

In order to guarantee the tightness of the vehicle - against water, air, dust and noises, Adhex offers a range of resistant and durable gaskets that can be positioned outside as well as in the passenger compartment or engine block.

Die-cut adhesive parts for acoustic protection of vehicles

Adhex develops for vehicle manufacturers a range of adhesive parts contributing to sound insulation and absorption to contribute to a quieter drive.